團結、創新、誠信、務實!

團結、創新、誠信、務實!  過硬的產品,優質的服務,合理的價格!

過硬的產品,優質的服務,合理的價格!

雄厚實力 科學管理、先進的營銷理念和良好的信譽!

雄厚實力 科學管理、先進的營銷理念和良好的信譽!

對外貿易 自主研發 非標定制

團結、創新、誠信、務實!

團結、創新、誠信、務實!  過硬的產品,優質的服務,合理的價格!

過硬的產品,優質的服務,合理的價格!

雄厚實力 科學管理、先進的營銷理念和良好的信譽!

雄厚實力 科學管理、先進的營銷理念和良好的信譽!

對外貿易 自主研發 非標定制

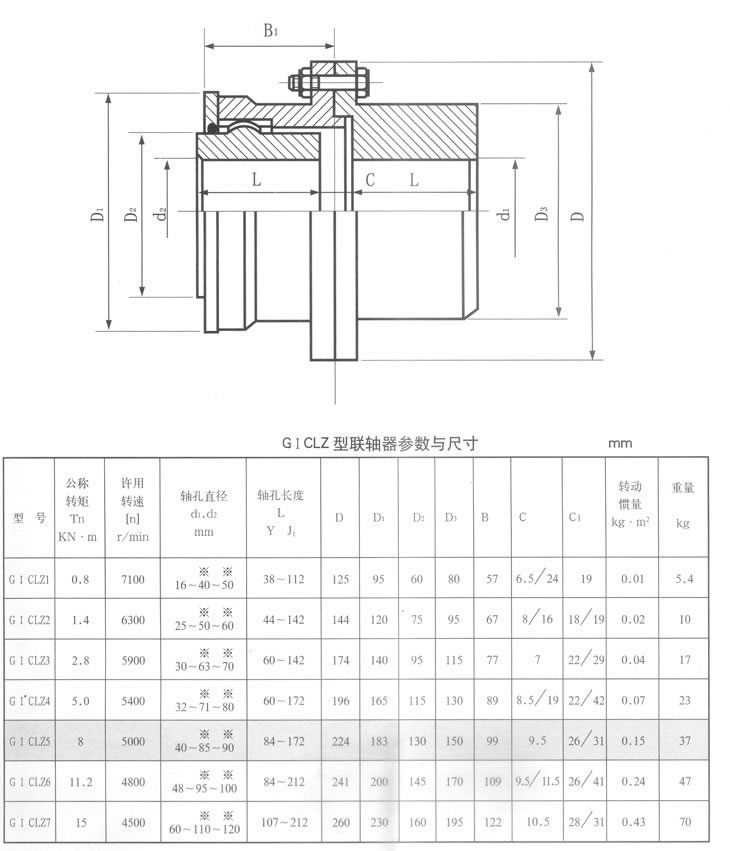

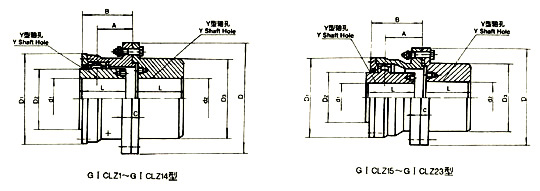

本聯軸器適用于聯接水平兩同軸線,并具有一定角向位移的傳動軸系。當被聯接兩軸端相距較遠時適用于采用CICLZ型,傳遞公稱轉矩為0.8~32000KN.m,工作環境溫度-20~+80℃ This coupling is applicable to the two coaxial lines of the connection level and the transmission shafting with a certain angular displacement. When the connection is far away from the shaft end is suitable for adopting CICLZ type, transfer the nominal torque 0.8 ~ 32000 kn. M, working environment temperature - 20 ~ + 80 ℃ Features of drum gear coupling The gear coupling is composed of the same inner ring and the flange half coupling of the outer tooth. Divided into straight teeth and drum tooth outside two kinds of tooth shape, tooth is the so-called drum will made spherical outer teeth, spherical center on the gear axis, backlash is generally large gear, drum gear couplings allows a larger angular displacement (as opposed to straight tooth coupling), can improve the tooth contact conditions, improve the ability to transfer torque, prolong service life. The contact state along the tooth width in angular displacement. Low coupling at work, two relative angular displacement of the shaft of the internal and external gear tooth surface of periodic axial relative sliding, inevitable formation of tooth surface wear and power consumption, therefore, the coupling should be in good and sealing state work. Type coupling radial size is small, large carrying capacity, often used for shaft transmission of working condition of low speed and heavy loading, high precision and the dynamic balance of coupling can be used for high-speed transmission, such as gas turbine shaft transmission. Because the drum type coupling Angle is greater than the direct coupling to the compensation, both at home and abroad widely used drum type coupling, straight type coupling are eliminated products, choose those should not choose as far as possible. The type I - sealing end is the separation type, the tooth spacing is larger, can allow larger radial displacement, can be connected with Y, J1, Z1. Ⅱ - sealed end to overall, tooth spacing is small, relative to allow the radial displacement is small, compact structure, and the moment of inertia is small, can be connected to Y, J1 type shaft extension. |